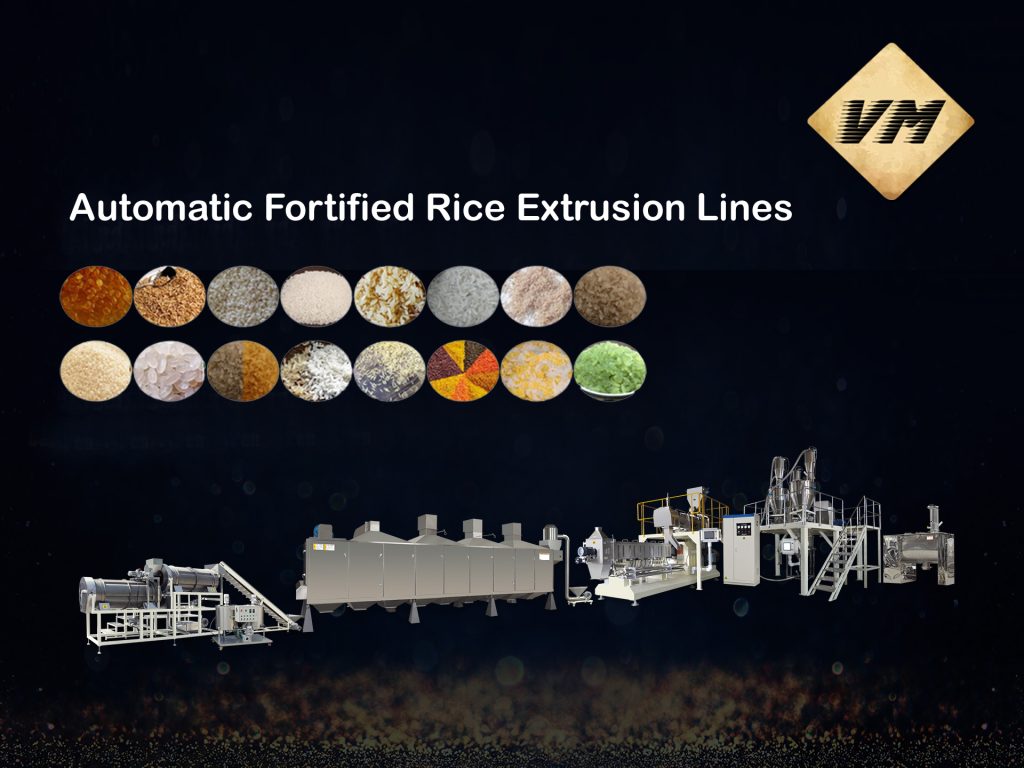

Fortified Rice Machine

A fortified rice machine is a specialized equipment used in the production of fortified rice, which is rice that has been enhanced with additional nutrients to address nutritional deficiencies. Here are some relevant keywords associated with fortified rice machines:

We are Specialised supplying of B.I.S Approved fully indian Manufactured of Fortified Rice machine, Contact +919953697613 VM Machines for Best Price. Fortified Rice making Plant.

Fortified Rice Machine

The Government of India has approved the Centrally Sponsored Pilot Scheme for Fortified Rice making plant on “Fortification of Rice and Its Distribution Under – Public Distribution System, Integrated Child Development Services, and Mid-Day Meal Scheme,” which is a cost-effective and complementary strategy to increase vitamin and mineral content in diets, a step towards nutritional security, and to combat anaemia and malnutrition in the nation. we are Providing Fortified Rice Making Plant Nationally & internationally. we are also BIS approved Manufacturer of Fortified Rice Machine.

Collecting broken rice grains that would otherwise have minimal market value is the first step in making fortified rice. These are used to create rice flour, which is subsequently mixed with nutrients. This combination is processed into a dough using a Twin Screw Rice Extruder, a device that separates kernels into rice-like shapes. Then, these kernels are added to regular rice in a set proportion.

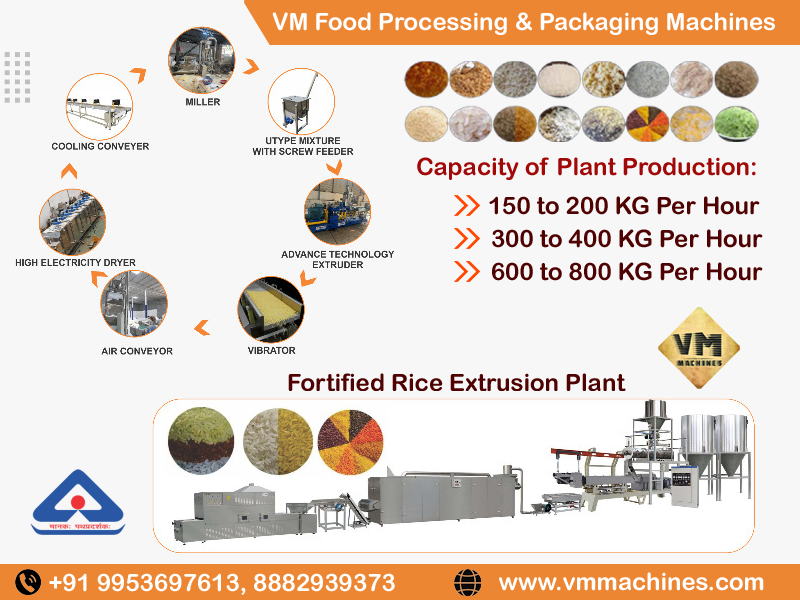

Manufacturer of fortified rice machine is VM Food Processing & Packaging Machines. From design, manufacturing, supply, erection, and commissioning, we take on turn-key projects. Our locally produced FRK Twin Screw Extruder comes in capacities ranging from 200 kg/hr to 2000 kg/hr.

A machine called a fortified rice extruder is made to combine rice with micronutrients like vitamins and minerals. The resultant reinforced rice grains can be consumed as food, giving those who might not have access to a diversified diet a more nutrient-dense choice. With the most recent technology, We VM Food Processing & Packaging Machines manufactures a full line of these fortified rice extruder machines.

we are the best Plant manufacturer of fortified rice making machine

Process of Fortified Rice Plant

There are various procedures involved in fortifying rice with vitamins. The first stage in the fortification process is to choose the proper micronutrients depending on the population’s nutritional needs and where the rice will be consumed. To make the micronutrients simple to combine with the rice, the second step is to blend them with a carrier, like dextrose or maltodextrin. To reach the correct nutritional levels in the finished product, the micronutrient blend is next combined with the rice at the proper ratio. The enriched rice is then packed and given to customers. best Manufacturer of Fortified Rice Making Plant from Delhi NCR

Process of Fortified Rice

There are various procedures involved in fortifying rice with vitamins. The first stage in the fortification process is to choose the proper micronutrients depending on the population’s nutritional needs and where the rice will be consumed. To make the micronutrients simple to combine with the rice, the second step is to blend them with a carrier, like dextrose or maltodextrin. To reach the correct nutritional levels in the finished product, the micronutrient blend is next combined with the rice at the proper ratio. The enriched rice is then packed and given to customers. best Manufacturer of Fortified Rice Making Plant from Delhi NCR

We offer these machines come in different types, each with its own set of features and capabilities. Here are some of the most common types of fortified rice extruder machines:

Twin Screw Extruder: This type of extruder uses two screws to mix the rice and micronutrient powder together. The twin screw design allows for more thorough mixing, resulting in more evenly fortified rice grains. Twin screw extruders are also able to handle a higher volume of rice, making them suitable for larger-scale operations.

Co-rotating Twin Screw Extruder: This type of extruder uses two screws that rotate in the same direction. The co-rotating design allows for more efficient mixing and better control over the extrusion process. These machines are often used for more complex recipes, such as fortified rice with multiple micronutrients.

Counter-rotating Twin Screw Extruder: This type of extruder uses two screws that rotate in opposite directions. The counter-rotating design creates a kneading effect that helps to evenly distribute the micronutrients throughout the rice. These machines are often used for high-precision operations, such as fortifying rice with sensitive micronutrients

Automatic Extruder: This type of extruder is equipped with an automatic feeder that allows it to continuously process rice without the need for manual intervention. Automatic extruders are typically more expensive than manual machines, but they can save time and labor costs in the long run.

Customized Extruder: This type of extruder is specially designed to meet the specific needs of a particular operation. Customized extruders can be equipped with a wide range of features, such as a modified screw design or a specialized die.

Benefits of our extruder:

One of the main benefits of using a fortified rice extruder is that it is a cost-effective way to fortify rice. Traditional methods of fortifying rice, such as blending or coating, can be expensive and time-consuming. The extruder, on the other hand, is a relatively simple and efficient process that can be done on a large scale. This makes it an ideal solution for fortifying rice in developing countries, where resources are often limited.

In addition to being cost-effective, the extruder is also a safe and reliable method of fortifying rice. The extrusion process is carried out at high temperatures, which kills any bacteria or other microorganisms that may be present in the rice. This ensures that the fortified rice is safe for consumption. The extruder is also easy to clean and maintain, which helps to reduce the risk of contamination.

Another advantage of using VM Machines fortified rice extruder is that it allows for the fortification of rice with a variety of micronutrients. The extruder can be adjusted to mix in different powdered micronutrient mixes, depending on the specific health needs of the population. This allows for a more tailored approach to fortifying rice, rather than using a one-size-fits-all method.

Some Important Features of Our Fortified Rice Extruder

Screw design: The screw design of the extruder is an important feature, as it determines the rate of extrusion, the temperature, and the pressure of the extruder, and us at VM Food Processing & Packaging Machines offers the finest screw designs.

Heating system: The extruder typically has a heating system that is used to heat the raw rice to a high temperature, which allows for the expansion of the rice and the release of the starch.

Die design: The die design of the extruder determines the shape and size of the final product. Different die designs can be used to produce different shapes and sizes of extruded rice with our machine

Cooling System: After the extrusion process, the rice needs to be cooled down quickly to prevent further cooking and to maintain the desired texture. For our extruder works properly

Control Systems: our extruders have control systems that allow the operator to adjust the temperature, pressure, and speed of the extruder, to ensure that the final product is of the desired quality.

Cleaning System: Extruders have cleaning systems that allow for easy cleaning of the machine after use, to ensure that the machine is hygienic and ready for the next batch of raw rice.

Power Source: Extruders can be powered by electricity or by other sources of power such as steam, depending on the model and the design.

Capacity: The capacity of the extruder is another important feature, our FRK Twin Screw Extruder is available from 300 kg/hr capacity to 700 kg/hr capacity.

Durability: our extruders are typically made from durable materials such as stainless steel, to ensure that they can withstand the high temperatures and pressures of the extrusion process.

VM Food Processing & Packaging Machines is among the leading manufacturer for machines in the concerned arena and generates processing plants. Apart from it, we take Turn-key projects starting from Design, Manufacturing, and Supply to Erection & Commissioning.

Some Keywords Related to Fortified Rice Extrusion Plant

- Fortified Rice Premix: A mixture of essential nutrients, such as vitamins and minerals, added to the rice during the production process.

- Automatic Pouch Packing Machine: Equipment used to automatically pack the fortified rice into pouches or bags.

- Fortified Rice Blender: A machine used to blend the fortified rice premix with rice kernels to ensure even distribution of nutrients.

- Fortified Rice Blending and Packing Machine: A combination machine that blends the fortified rice premix with rice kernels and then packs them into pouches or bags.

- Fortified Rice Kernels Plant: A facility specifically designed for the production of fortified rice kernels, which are the basic ingredient used in fortified rice production.

- Fortified Rice Plant: A general term for a facility that produces fortified rice, encompassing various stages of the production process.

- Fortified Rice Extrusion Plant: A plant equipped with an extruder, which is used to produce fortified rice using a high-pressure extrusion process.

- FRK Plant: A “FRK plant” refers to a facility dedicated to the production of Fortified Rice Kernels. Fortified Rice Kernels are rice grains that have been enriched with essential nutrients like iron, folic acid, and vitamins. This fortification process aims to combat malnutrition, particularly in regions where rice is a staple food. By establishing FRK plants, communities can address micronutrient deficiencies, which can have severe health implications, especially for vulnerable groups such as children and pregnant women. These plants play a crucial role in enhancing public health by providing a convenient and widely consumed vehicle for delivering vital nutrients to large populations. Investing in FRK plants is a significant step towards improving overall well-being and combating malnutrition on a broader scale.

- Artificial Rice Plant: Another term for a fortified rice plant, emphasizing the process of creating rice-like grains with added nutrients.

- Fortified Rice: Rice that has been enriched with essential nutrients to combat nutritional deficiencies.

- 78 Fortified Rice Extruder: Refers to a specific model or type of extruder machine used in the production of fortified rice.

- 75 Fortified Rice Extruder: Refers to another specific model or type of extruder machine used in the production of fortified rice.

- FRK Rice Processing Line: A production line dedicated to processing fortified rice kernels, including cleaning, blending, and extrusion steps.

- Fortified Rice Plant Suppliers: Companies or organizations that supply fortified rice plant machinery, equipment, and technology.

- Fortified Rice Processing Line: A series of processing steps, typically involving blending, extrusion, and packaging, for the production of fortified rice.

- BIS Approved Fortified Rice Production Line: BIS (Bureau of Indian Standards) approval signifies that the fortified rice production line complies with specific quality and safety standards set by the Indian regulatory authority.

For more Information for Fortified Rice Making Plant …..Contact our Sales Team

#Fortified Rice Plant #Fortified Rice Extrusion Plant #FRK plant #Artificial Rice Plant # Fortified Rice, #78 Fortified rice Extruder #75 Fortified Rice Extruder #FRK Rice Processing Line #Fortified Rice Plant Suppliers #Fortified Rice Processing Line #BIS approved Fortified Rice Production Line #fortified rice machine